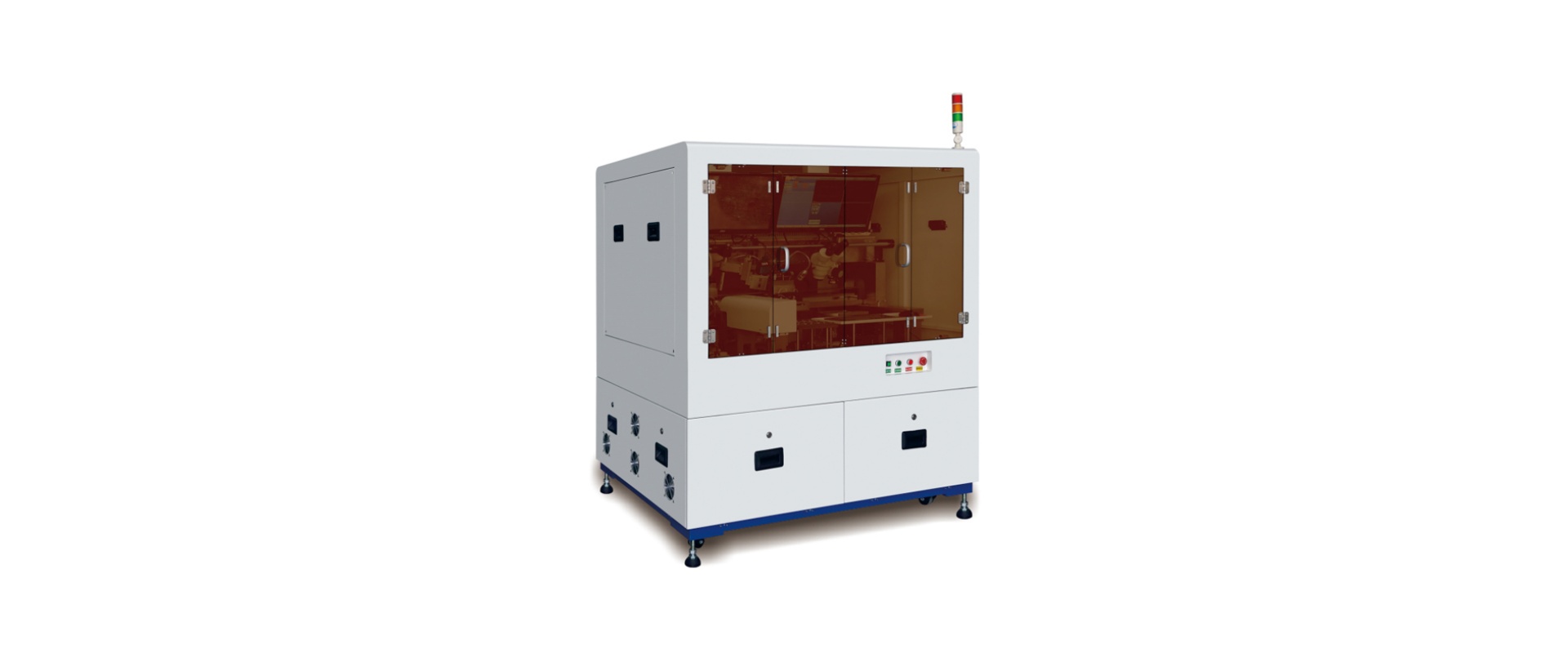

Eutectic Die Bonder

Eutectic Die Bonder HJC-560E

Solution customized. A specialized production equipment that heats and bonds the heat sink (Submount) and chip (LD) onto the TO56 socket.

Machine Introduction:

This device is a specialized production equipment that heats and bonds the heat sink (Submount) and chip (LD) onto the TO56 socket.

Simultaneously eutectic two materials (heat sink and chip) on the same socket, simplifying the packaging process and improving the yield of finished products.

Heat sink and chip blue film loading, independent identification, picking and placement, calibration. The pipe seat incoming material realizes the assembly line of loading and unloading, improving production efficiency.

Visual recognition and positioning of chip luminous lines, with position and angle compensation to ensure installation accuracy.

The mechanical arm suction nozzle vacuum picks up and places the material, and the flow sensor detects whether the material is successfully sucked, and is equipped with a nitrogen vacuum breaking device. Ensure production accuracy. The suction pressure is small and stable.

The eutectic stage constant temperature mechanism has a stable temperature setting and nitrogen protection during the production process. Ensure the reliability of eutectic.

Robot X, The Y-axis is controlled by a linear motor, ensuring accuracy while improving production efficiency.

Equipment Function:

This equipment is a production equipment that combines the heat sink (Submount) and chip (LD) in the COB process, which are heated and bonded onto the tube socket.

Manual feeding:

Manually place the heat sink and chip separately in the heating wafer mechanism and chip wafer mechanism;

Manually place the pipe seat in the feeding mechanism;

Automated workflow:

After starting the device, the automatic assembly line transports the tube seat to the tube seat workbench and fixes it.—>The tube seat handling robot picks up the tube seat and moves it to the flipping finger.—>The flipping finger sends the tube seat to the eutectic table.—>CDD1 searches for positioning enthusiasm.—>The heat sink picking robot picks up the heat sink and moves it to the top of CCD7.—>CCD7 identifies and corrects the heat sink on the back.—>The heat sink picking robot places the heat sink at the designated position on the tube seat.—>CCD5 searches for positioning chips.—>The chip picking robot picks up the chip and moves it to the calibration table.—>CCD4 identifies and corrects the front of the chip.—>The chip mounting robot moves the chip to the top of CCD6.—>CCD6 identifies and compensates for the back of Is it correct—>The position is correct (correct it again if not correct)—>The chip mounting robot places the chip in a heat sink and heats it for bonding (CCD2 and CCD3 observe the eutectic situation in real time) —>Flip the fingers to remove the eutectic product from the eutectic stage and flip it 90 °.—>The tube holder handling robot moves the eutectic product to the tube holder workbench for loading.—>When all the tube holders on the workbench fixture are eutectic, the product is transported to the cutting mechanism through the assembly line.

Eutectic Die Bonding

Shell and chip eutectic bonding. Chip with wafer loading; Shell with tray loading;

Nitrogen protection