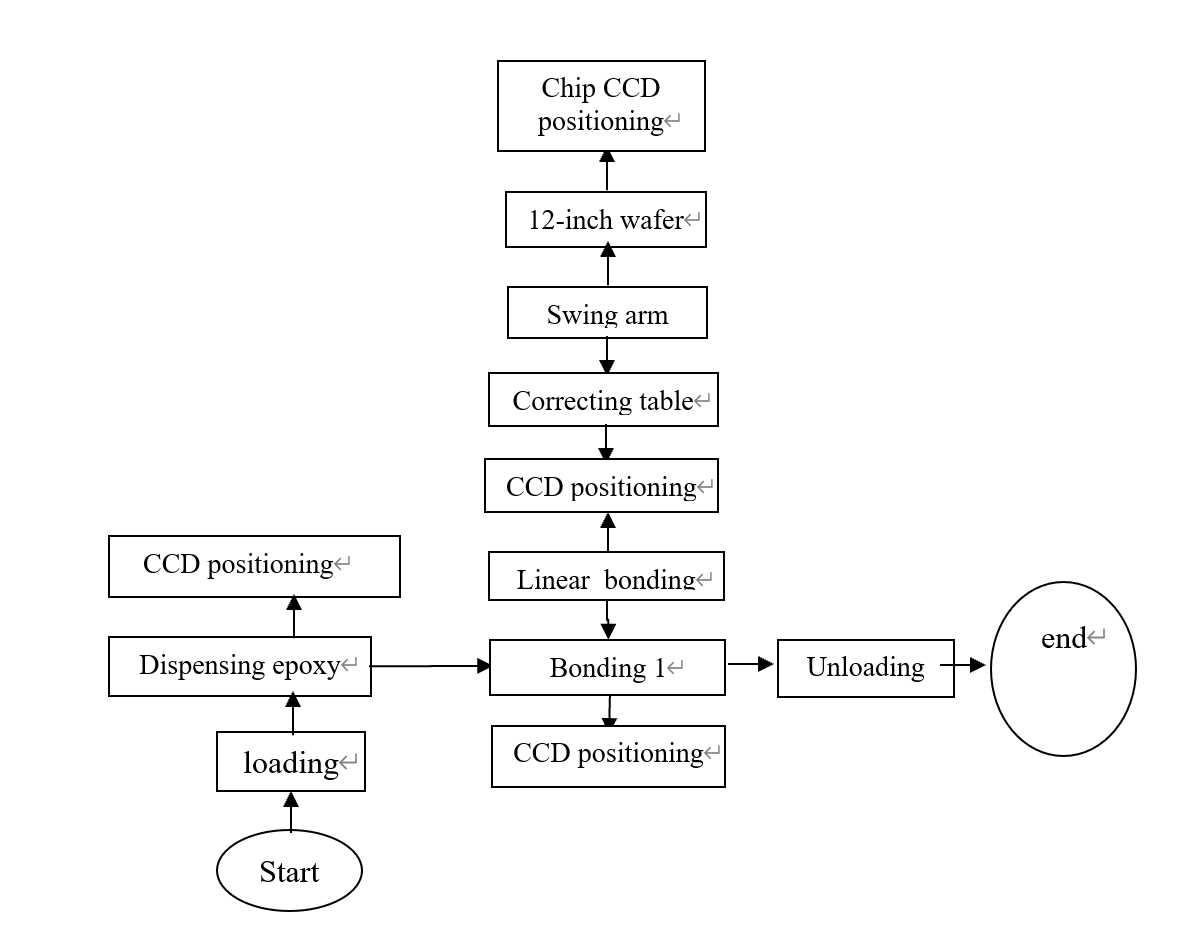

Die Bonder

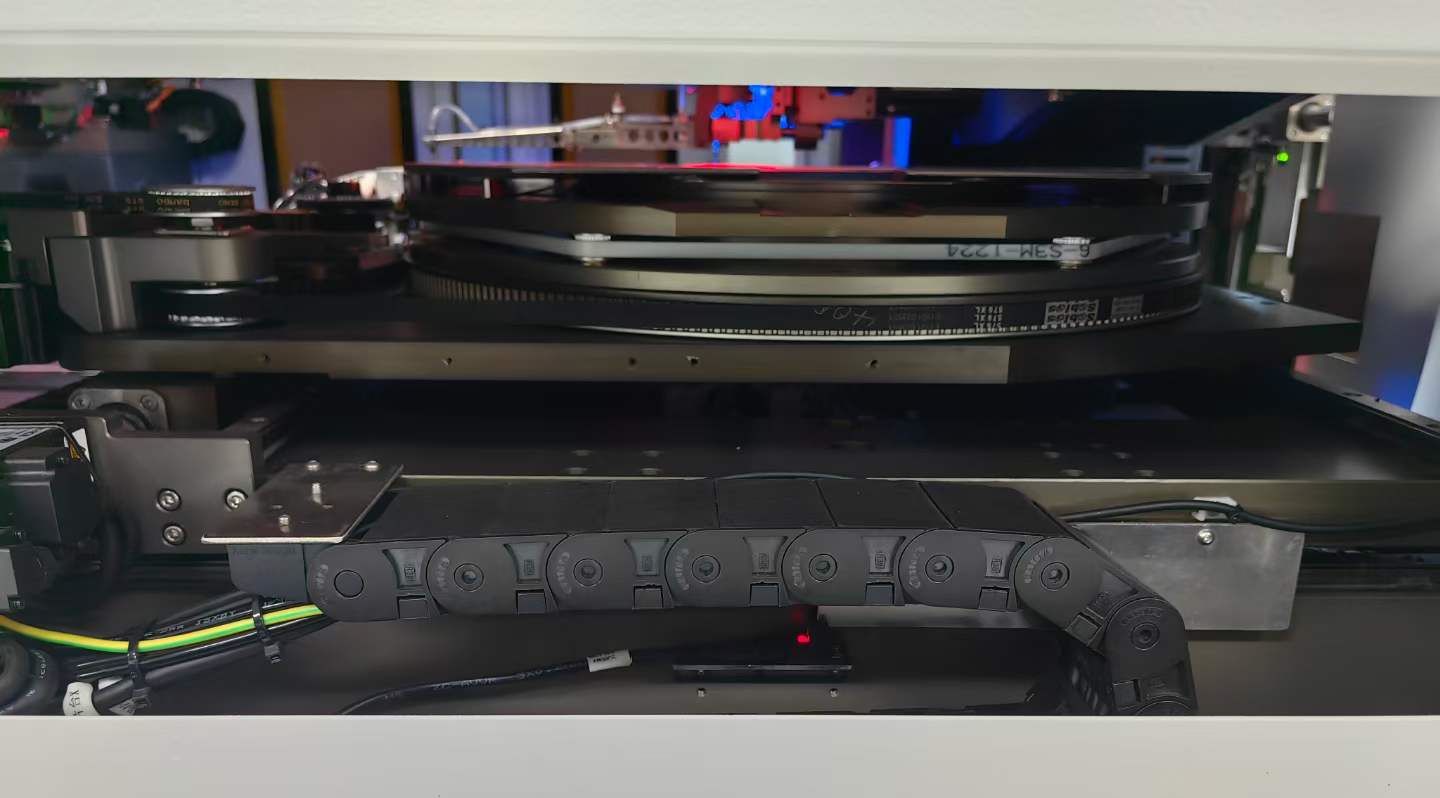

Die Bonder HJC-560D

Automatic die bonding machine, die attach equipment. Waffer automatic loading and unloading is optional.

Machine Features:

- Direct drive bonding head with 180 ° swing arm rotation.

- Multi ejector pin design for easy adaptation to different types of die sizes.

- 1.3 million resolution visual system for positioning chips and frames.

- Vision live position, accurate picking even after chip moved on tape.

- 5. Manual loading and unloading with fixture.

- 6. The wafer ring fixture can be used for 12 inch, 8 inch, and 6 inch iron ring wafer.

- Accurate chip counting function.

- English/Chinese two version languages.

- Can be connected with MES. (Optional)

Discover the Power of High-Precision Chip-On-Substrate Bonding

Watch our detailed video to see how our advanced chip-on-substrate bonding technology can revolutionize your production process. Witness the precision, efficiency, and reliability that our product brings to the table.

Re:Die Bonder HJC-560D

SPECIFICATION

| Product application | MEMS, Storage, CIS, optoelectronics, etc | |

| Accuracy | ± 1.5um (standard patch) | |

| Equipment efficiency | 5S (standard patch, one pick&place); Excluding temperature curve | |

| Installation system | X/Y/Z | Travel: 350mmx500mmx50mm |

| Rotation axis | Travel: 360 °; Repetitive positioning accuracy: 0.02 ° | |

| Minimum suction size | 0.15*0.2mm | |

| Suction nozzle | Automatic nozzle replacement, one nozzle holder supports 13 nozzles | |

| pressure | 10-2000g (pressure real-time closed-loop feedback) | |

| Material system | Standard configuration | 2×2″/4×4″ gel pack/waffle pack |

| Standard configuration | 6 “/8” blue film system | |

| Preheating workbench | Temporary carrier board | Supports both soft and hard boards; Supports large-sized carrier boards |

| size | 300x300mm, customizable | |

| temperature range | 25-200℃ | |

| Flip system | Optional configuration | 180 ° flipping, customized for specific application nozzles |

| vision system | type | Two down view cameras and one high magnification up view camera |

| light source | Each camera is equipped with 4 programmable lights (collimated white light, circular RGB tricolor light) | |

| Factory requirements | source | 200-240VAC 50HZ single phase 20A |

| compressed air | 0.6Mpa 300L/min | |

| nitrogen | 0.3Mpa 30L/min 99.9% or higher | |

| vacuum | minus 80kpa 120L/min (Pipeline vacuum or vacuum pump) | |

| Weight | Around 2000kg |